Japan PET Resin Trade, Fibers, Apps & Recycling/RPET

日本の PET 樹脂取引、繊維、応用およびリサイクルについて

20-21 Apr, 2015 - Tokyo, JAPAN

Hilton Tokyo

Japan PET Resin Trade, Fibers, Apps & Recycling/RPET

日本の PET 樹脂取引、繊維、応用およびリサイクルについて

Hilton Tokyo

| |||||||||||||||||||||||||||||||||||||||||||||||

Japan, the second largest retail market in the world, is witnessing a rise in 'konbini' convenience stores. This is a significant change in the evolving retail landscape in the country where large departmental stores were more popular until recently.

Consumers are said to have moved away from weekly shopping trips and prefer konbinis.

In fact the number of konbini convenience stores have increased over the last few year - 48,139 in 2012, with another 3,700 stores opened by 2013, increasing the total number of 'konbini's' to 56,820.

This trend has a ripple effect on the packaging industry in the country. There is a need for dramatic change to the formats, portion sizes of packaging to suit the small size of konbinis - which roughly have an average floor area of less than 100m².

Further the packaging industry need to adopt technologies such as lightweighting and downsizing its products too.

The limited shelfspace in konbini convenience stores will lead to more limited linear, or horizontal, product display space. Thus, packaging has to be typically taller but with a narrower footprint.

More interesting and innovative trends from Japan's packaging industry will be under the spotlight at CMT's inaugural JPET (Japan PET Resin Trade, Fibers, Apps & Recycling/RPET) on 20-21 April, 2015 at the Hilton Tokyo.

More details available with Ms. Hafizah - email hafizah@cmtsp.com.sg or call +65 6346 9218.

23 Mar, 2015

PRESS RELEASE

BericapValve dosing valve made of TPE

It is now more than two year since BERICAP first launched the 'BERICAPValve' dosing valve on the market.

Several squeezable valves are now used for squeezable food products, most of them made of silicone. The BERICAPValve is different because it is made of TPE, which has the advantage, that - unlike the commercial silicone valves - it prevents contamination in the recycling process.

BERICAP's bi-injected dosing valve closures offer a perfect product security and support controlled dosing of products such as honey.

Honey is traditionally packed in glass jars closed with aluminium twist-off closures as well as in squeezable PET bottles using FlipTop closures with silicone valves. Now it seems that French honey bottlers are showing considerable interest in the TPE valve. The reason is twofold: it is easy to recycle without contaminating the recycling stream and, in addition, the taxes payable for a TPE valve are lower than those for a silicone valve.

The BERICAPValve is available in various shore hardness and cut lengths in order to suit various products other than honey, such as ketchup, chocolate syrup, body lotion and pharmaceutical products, all having individual viscosities. Even products containing pieces, such as cocktail sauces, are easy to dose with the BERICAPValve.

BERICAP offers a wide range of hinged closures in which the bi-injected BERICAPValve can be inserted. Customised designs can, of course, be developed in the BERICAP R&D centres.

BERICAP in profile:

![]() BERICAP is a global manufacturer of plastic closures with 22 factories in 19 countries across the world, ongoing projects in several countries in Asia and the Middle East and a network of licensees and partners to supply similar products made to the same quality and service standards to its global customers. With 4 main R&D centres in France, Germany, Spain and Turkey, a mould shop in Hungary and several satellite R&D offices in its main operations, BERICAP is particularly committed to developing innovative plastic closures to support its customers' success.

BERICAP is a global manufacturer of plastic closures with 22 factories in 19 countries across the world, ongoing projects in several countries in Asia and the Middle East and a network of licensees and partners to supply similar products made to the same quality and service standards to its global customers. With 4 main R&D centres in France, Germany, Spain and Turkey, a mould shop in Hungary and several satellite R&D offices in its main operations, BERICAP is particularly committed to developing innovative plastic closures to support its customers' success.

For more information please contact:

Martina Mussel Marketing Communication

BERICAP, Kirchstraße 5 , D - 55257 Budenheim

Tel. +49 6139 29 02 0 - Fax +49 6139 29 02 188 - email martina.mussel@bericap.com - www.bericap.com.

11 Mar, 2015

PRESS RELEASE

It may now be common practice in many countries around the world to recycle closures, but it may be even better to use closures for a second time, especially if this can be connected with specific marketing campaigns. A second use concept is ecologically sound, socially of interest and economically justifiable.

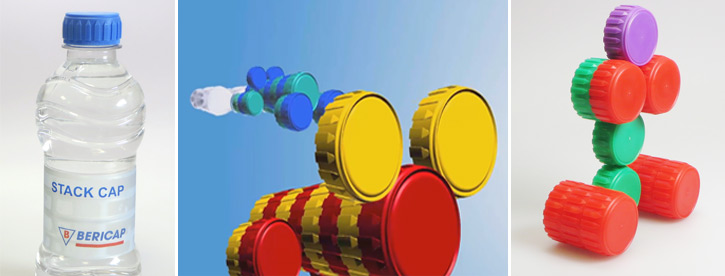

StackCap is based on a concept developed by Smooth HIP Ltd and has been enhanced to a high-performance beverage cap by Bericap. StackCap meets the current trend towards the 2nd use of caps and closures. They are used first to cap still or carbonated beverages and subsequently to build toys or other artistic shapes.

StackCaps can be stacked on top of each other or be assembled side by side by means of grooves. This allows 3-dimensional structured toys such as cars, trucks, planes or houses to be built. When combined with the empty PET bottle, toy rockets, space ships, swimming platforms, towers or poles for street games can be constructed. The secondary use of packaging thus also has an educational value in developing hand-to-eye coordination.

StackCap can be used for promotions or to distinguish children packs on the shelf. The closure can be used for contests or to create community and can serve as a brand ambassador in the consumer's possession.

StackCap is currently available for the neck finish PCO 1881. StackCap adds only a little additional weight compared with the standard flat cap.

StackCap can be applied on a standard capper, but then requires a distinct chuck.

BERICAP in profile:

![]() BERICAP is a global manufacturer of plastic closures with 22 factories in 19 countries across the world, ongoing projects in several countries in Asia and the Middle East and a network of licensees and partners supplying similar products made to the same quality and service standards to its global customers. With 4 main R&D centres in France, Germany, Spain and Turkey, a mould shop in Hungary and several satellite R&D offices in its main operations, BERICAP is particularly committed to developing innovative plastic closures to support its customers' success.

BERICAP is a global manufacturer of plastic closures with 22 factories in 19 countries across the world, ongoing projects in several countries in Asia and the Middle East and a network of licensees and partners supplying similar products made to the same quality and service standards to its global customers. With 4 main R&D centres in France, Germany, Spain and Turkey, a mould shop in Hungary and several satellite R&D offices in its main operations, BERICAP is particularly committed to developing innovative plastic closures to support its customers' success.

For more information please contact:

Martina Mussel Marketing Communication

BERICAP, Kirchstraße 5 , D - 55257 Budenheim

Tel. +49 6139 29 02 0 - Fax +49 6139 29 02 188

email martina.mussel@bericap.com

21 Jan, 2015